MODUL MT Verzahntechnik GmbH

About us

Based on a tradition dating back to 1900, VEB Zahnschneidemaschinenfabrik MODUL was founded in 1950. MODUL MT is now a competence center for gear milling and offers an extensive program for the soft manufacturing of different gears. Their range includes machines for milling cylindrical gears and shafts with straight and helical gears, for chamfering with forming or cutting tools and for manufacturing straight bevel gears.

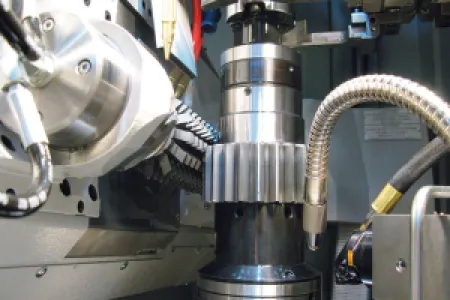

Gear cutting machines from MODUL are the safe choice when it comes to precise and efficient machining and manufacturing of gears. MODUL has repeatedly set new standards in innovative gear manufacturing technologies since 1950.

MODUL offers hobbing, skiving, chamfering, deburring gear machining to cover the complete technology range for soft machining of gears. Hobbing and skiving in particular can also be used for hard machining of gears.

MODUL gear cutting machines are successfully used in countless sectors: from automotive and e-mobility, aerospace, agricultural machinery and commercial vehicles trough to rolling stock.

MODUL gear cutting machines are ideal for gears, including those for transmissions and on wheelsets, shafts with multiple gears, gears made from special materials, gears on crankshafts as well as for milling and chamfering / deburring.

MODUL gear cutting machines meet the highest quality and precision demands in the aerospace and automotive industries.

Address

Schulstr. 63

09125 Chemnitz

Germany

E-mail: info@modul-mt.com

Phone: +49 371 576-0

Internet: modul-mt.com

MODUL H80 - H200

Machines for max. workpiece diameter 80 mm / 100 mm / 130 mm / 200 mm, up to module 5 mm

Used e.g. in the automotive industry, general mechanical engineering, pumps

Compact, highly rigid machine (small footprint)

· Closed frame structureMachining of gears and shafts

Axial travel 400 mm

Use from single part production to large series

· Manual loading or flexible automation (fast gantry loader with double gripper or robot)Easy integration into production cells

Dry and/or wet machining possible

· Stainless steel bevels in the work area

· Excellent chip removal

· Clear work area layout to prevent chip nestsHard machining of gears (skiving)

Tool-free set-up as an option (quick-change clamping and gripper)

MODUL H250 - H400

Machines for max. workpiece diameter 250 mm / 300 mm / 400 mm, up to module 8 mm

Use e.g. in general mechanical engineering, automotive and truck industry, supplier industry

Various milling heads for a wide range of applications

· High speeds, e.g. when using carbide tools

· High torques for gearing up to module 10 mmMachining of gears and shafts (long shafts up to 2,000 mm in vertical clamping)

Worm gears and worms

· Worm milling can also be realized without attachment head(axial travel 600 mm)

Use from single part production to large-scale production

Manual loading or flexible automation with double gripper

· Portal loader

· Various ring loaders (2 or 4 stations) up to 50 kg workpiece weight

· Robot loading directly onto the machine table or transfer to RL gripperSimple integration into production cells

Dry and/or wet processing possible

· Stainless steel bevels in the work area

· Excellent chip removal

· Clear work area layout to prevent chip nestsHard machining of gears (skiving)

Flex package as an option

· Tool-free set-up (quick-change clamping and gripper)

· NC-controlled coarse burr stripper (ideal for processing wheels and shafts on one machine and

for a wide range of workpieces)

· Counter stand as NC axis

MODUL H600 - H800

Machines for max. workpiece diameter 600 mm / 800 mm; max. module 22 mm

Axial travel 800 mm

Use e.g. in general machine and gear construction

Various milling heads available for the respective application

Machining of e.g. gears and shafts, worm gears, rotors

Compact machine design

Hook machine

Very good accessibility and clarity of the work area

Manual loading or automation (ring loader up to 150 kg workpiece weight) or robot

MODUL H 900 - H2300

Machines for max. workpiece diameters 900 mm / 1500 mm / 2,300 mm; max. module 28 mm

Axial path 1,400 mm

Hobbing, profile milling

Machining of gears or shafts, version with or without counter-stand

Automatic centering of pre-toothed workpieces

Optional milling head for internal gears, also interchangeable

MODUL VS 250

Modul VS 250 skiving machines ensure maximum yield rates in the high performance range from single part and small series production to mass production. These skiving machines can be used to produce high-quality external and internal gears on workpieces up to 250 mm in diameter and gear module 6 by multi-cut machining in large quantities. The skiving machines are suitable for dry and wet machining with oil or emulsion as well as for soft and hard machining.

Enhanced performance

Modul VS 250 skiving machines enable dry and/or wet machining using tools made of high speed steel, carbide or other modern materials and soft machining or finished milling of hardened gears.

Maximum flexibility

Modul VS 250 skiving machines can be equipped with a tool changer. This enables the execution of a numerous operations and auxiliary functions, such as chamfering and deburring of gears and drilling or turning. An optional holder enables the machining of shafts.

Greatest overall efficiency

Modul VS 250 skiving machines offer high cutting performance with reduced setup times. Tool replacement can be performed during operation and does not result in downtimes.

Ideal automation

Modul VS 250 skiving machines permit manual loading, automation via gantry loaders or feeding via an external loading system (e.g. robot).