Hartmetall-Werkzeugfabrik Paul Horn GmbH

About us

Whichever alloys you have to machine, Horn has an innovative tool solution.

As a technology leader, we set the standards in this high technology sector - with more than 25,000 precision tools and over 200,000 application solutions implemented to date. When it comes to innovations, we always consider factors that contribute to success. From carbide production through interfaces and tool holders to coating technologies and geometries, we can control all important factors ourselves. Developing and possessing this extensive know-how is one of our strengths and benefits each individual customer by delivering targeted financial savings.

EXPLORE HORN

Address

Horn-Strasse 1

72072 Tübingen

Germany

E-mail: info@de.horn-group.com

Phone: +49 7071 7004-0

Internet: www.horn-group.com/de/

700/712 Moo 1 Tambol Panthong

20160 Amphur Panthong, Chonburi Province

Thailand

E-mail: info@th.horn-group.com

Phone: +66 33 135-060

Internet: www.horn-group.com/th/

Contact person:

Michael Mellerup

Managing Director Horn Cutting Tools Thailand Ltd

E-mail: michael.mellerup@th.horn-group.com

Products & Services

Fields of application: High-precision tools and accessories for radial grooving, face grooving, profile grooving, parting off, slot broaching, gear skiving, gear cutting, high-polish turning, threading, machining of pipes and sleeves, groove milling, slot milling, cut-off milling, thread milling, polygon turning, thread whirling, high-polish milling, finish boring, face milling, shoulder milling, profile milling, rotary milling, reaming and drilling. Additive manufacturing / 3D printing processes (selective laser melting), carbide blanks and wear parts.

Production portfolio: 25,000 standard tools, more than 200,000 special solutions

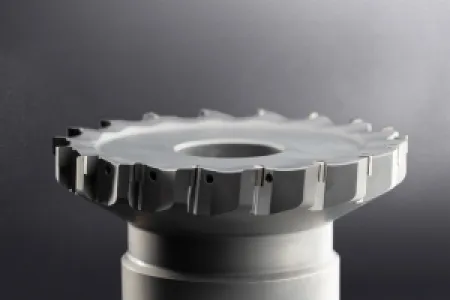

PCD MILLING TOOLS

PCD Milling programme for machining aluminium, non-ferrous metals and composite materials

Customized face milling concepts

Comprehensive semi-standard

Supermini with sintered Geometry

Insert with sintered chip breaking geometry for boring operations

High process reliability due to excellent chip control in different materials

Suitable for internal, face, copy and back turning

Supermini with sintered Geometry for threading

Sintered chip breaking geometry for threading

High process reliability due to excellent chip control in different materials

Universally applicable for variousthread diameters

Broaching System 117

Broaching from a bore diameter of 9 mm with indexable insert

Extensive product range available from stock

Suitable for conventional broaching and broaching units

Wälzschälen mit Wendeschneidplatten

For module 5 to 8

Increased efficiency due to double-edged indexable inserts

Precise insert seating for high repeatability

-thumb.webp)

-thumb.webp)